Personnel grounding devices are the primary means of ESD control. For static charges generated during ordinary body movements, personnel-grounding devices provide a permanent path to ground. Such devices may take various forms such as:

- Wrist Straps

- Leg Straps

- Heel Straps

- Conductive Shoes

Wrist Straps

Wrist straps are considered to be the first line of defense against ESD and shall be required in the majority of ESDS work environments. Metallic contacts are preferred over conductive plastics. The wrist strap cuff shall always be in direct contact with the operator’s bare skin. It must never be worn over clothing. Bead-type chain wrist straps are prohibited.

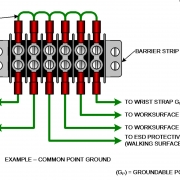

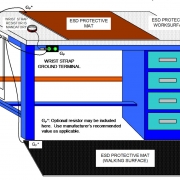

Wrist straps shall always be worn snugly against the skin and shall not dangle freely. The electrical integrity of each wrist strap shall be checked during initial certification and verified by the operator at the beginning of every shift during which it is used. A wrist strap checker specifically designed for that purpose shall be used to verify the wrist-strap is functional. The wrist straps shall be connected to ground using one common ground point for each workstation. ESD S6.1 “Grounding Recommended Practice” outlines the recommended grounding practices.

Continuous, in-line continuity checkers are highly recommended. (Reference ESD TR20.20-2008, Section 5.3.9 – Continuous Monitors). The electrical resistance of the wrist strap measured between the opposite hand and the (ungrounded) grounding end of the wrist strap assembly shall not exceed 9M ohms above the value of the incorporated current-limiting resistance. The static dissipative work surface material shall never be used as part of the series path to ground for a wrist strap.

More information on wrist strap testing and set up is available on ESDS1.1 “ESD Standard Test Method for the Protection of ESDS Items – Wrist Straps”.

Leg Straps, Heel Straps, and Conductive Shoes

A conductive/dissipative floor and/or conductive floor mats are required when using leg straps, heel straps, and conductive shoes as acceptable alternatives to a wrist strap in those instances where the use of a wrist strap is impractical or unsafe. Examples of such instances would include working near moving conveyor belts or wave soldering machines and when working on large systems. The foot strap should have a built-in resistance of 1X106 +/- 20 percent. If the resistance does not meet this recommendation, the value should be approved by the ET&V Officer.

The ET&V Officer shall measure the conductivity of leg straps, heel straps, and conductive shoes during the initial certification. The operator shall verify this conductivity for each work shift. Test methodology is found in ESD S9.1 “ESD Association Standard Test Method for the Protection of ESDS Susceptible Items – Footwear – Resistive Characterization”.

Leave a Reply

Want to join the discussion?Feel free to contribute!