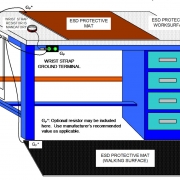

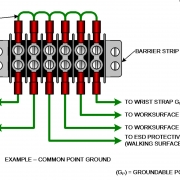

All permanent and semi-permanent metallic structures and test equipment utilized during handling or manufacturing of ESDS components or hardware shall be grounded using a common point ground. A major goal of this document is to ensure that all conductive materials are tied together at the same potential. An equal potential workstation is the secret to preventing damage to ESDS components.

The practice of having a separate ESD ground from the third wire (green) alternating current (AC) ground is wide spread but has the potential for damaging components because it places the operator and the work surface at a different ground potential with respect to any soldering irons and/or test equipment. The recommended practice is to use the third wire AC line ground for grounding all items at the ESDP workstation. When a separate grounding line is present or used in addition to the equipment ground, it must be bonded to the equipment ground at each ESDP station to minimize the difference in potential. ANSI EOS/ESD S6.1 “ESD Association Standard for the Protection of ESDS Items – Grounding-Recommended Practice” contains detailed hookup diagrams for ESDP workstations and support equipment.

The resistance of the conductor from the groundable point of the work surface, wrist strap, walking surface or other items to the common point ground should not be greater than 1.0 ohm. If a series resistor is used in the circuit, the total resistance shall be the value of the resistor.

The resistance of the conductor from the common point ground to the equipment ground should not be greater than 1.0 ohm.

The impedance (AC resistance) of the equipment-grounding conductor from the common point ground to the neutral bond at the main service equipment should not be greater than 1.0 ohm.

Each ESDP workstation should have a grounding block that provides sufficient wrist strap connections for all potential users. These grounding points shall not utilize portions of the protective work surface as a series element to complete the ground circuit. Receptacle grounds in an EPA shall be verified at least semiannually.

A good example of ESDP workstation setup is shown in Figure 6.5.1 Typical ESD Protective Station Grounding Systems and in ESD TR20.20-2008, Figure 13.

Stools and Chairs

Personnel performing ESDS tasks while seated should use ESDP stools and chairs. Only chairs of metallic frame construction shall be used in an EPA. Class 1 facilities shall provide ESDP chairs or stools at the workstation if seating is required. Test methods are found in ESD STM 12.1 “ESD Association Standard Test Method for the Protection of ESDS Items – Seating – Resistive Characterization”

Leave a Reply

Want to join the discussion?Feel free to contribute!